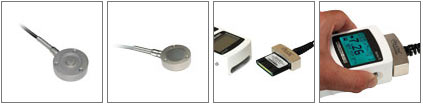

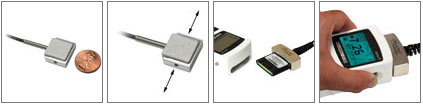

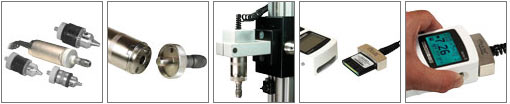

Mark-10 M3i/M5i/M7i Plug & Test™ Remote Force/Torque Sensors

Force Sensors

Mark-10 Tension and Compression Force Sensor Series R01

A rugged force measurement sensor for tensile and compressive forces up to 10,000 lb. Durable S-Beam architecture allows for many applications and setups. Solid steel construction ensures many years of use in factory or laboratory environments.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Measures tensile and compressive forces

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.15% of full scale ±1 digit + indicator

- Weight: From 1.9 lbs (0.9 kg) to 3 lbs (1.4)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||

| lbF | ozF | gF | kgF | N | kN | |

| MR01-50 | 50 x 0.02 | 800 x 0.5 | 25000 x 10 | 25 x 0.01 | 250 x 0.1 | - |

| MR01-100 | 100 x 0.05 | 1600 x 1 | 50000 x 20 | 50 x 0.02 | 500 x 0.5 | - |

| MR01-200 | 200 x 0.1 | 3200 x 2 | - | 100 x 0.05 | 1000 x 0.5 | 1 x 0.0005 |

| MR01-500 | 500 x 0.2 | 8000 x 5 | - | 250 x 0.1 | 2500 x 1 | 2.5 x 0.001 |

| MR01-1000 | 1000 x 0.5 | 16000 x 10 | - | 500 x 0.2 | 5000 x 2 | 5 x 0.002 |

| MR01-1500 | 1500 x 1 | 24000 x 20 | - | 750 x 0.5 | 7500 x 5 | 7.5 x 0.005 |

| MR01-2000 | 2000 x 1 | 32000 x 20 | - | 1000 x 0.5 | 10000 x 5 | 10 x 0.005 |

| MR01-5000 | 5000 x 2 | - | - | 2500 x 1 | 25000 x 10 | 25 x 0.01 |

| MR01-10000 | 10000 x 5 | - | - | 5000 x 2 | 50000 x 25 | 50 x 0.02 |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| lbF | kgF | N | kN | |

| MR01-50 | 50 x 0.05 | 25 x 0.02 | 250 x 0.2 | - |

| MR01-100 | 100 x 0.1 | 50 x 0.05 | 500 x 0.5 | - |

| MR01-200 | 200 x 0.2 | 100 x 0.1 | 1000 x 1 | - |

| MR01-500 | 500 x 0.5 | 250 x 0.2 | 2500 x 2 | - |

| MR01-1000 | 1000 x 1 | 500 x 0.5 | 5000 x 5 | - |

| MR01-1500 | 1500 x 2 | 750 x 1 | 7500 x 10 | - |

| MR01-2000 | 2000 x 2 | 1000 x 1 | 10000 x 10 | - |

| MR01-5000 | 5000 x 5 | 2500 x 2 | - | 25 x 0.02 |

| MR01-10000 | 10000 x 10 | 5000 x 5 | - | 50 x 0.05 |

Dimensions

Ordering Information

| Model | A | B | C | D | E |

| MR01-50 | 2.40 [61.0] |

2.00 [50.8] |

0.46 [11.7] |

0.65 [16.5] |

1/4-28 UNF |

| MR01-100 | |||||

| MR01-200 | |||||

| MR01-500 | 0.71 [18.0] |

0.90 [22.9] |

1/2-20 UNF | ||

| MR01-1000 | |||||

| MR01-1500 | 0.96 [24.4] |

1.15 [29.2] |

|||

| MR01-2000 | |||||

| MR01-5000 | 3.90 [99.1] |

3.00 [76.2] |

3/4-16 UNF | ||

| MR01-10000 | |||||

| Additional Items to Consider | |||||

| AC1018 | Mounting kit, R01/R03 to force test stand | ||||

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector | ||||

Mark-10 Compression Force Sensor Series R02

Button sensor for compressive loads of up to 10,000 lb. Compact and rugged, the R02 is ideal for heavy duty applications with space constraints.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Small size

- Stainless steel construction

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.5% of full scale ±1 digit + indicator

- Weight: 0.4 lbs (0.2 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||

| lbF | ozF | gF | kgF | N | kN | |

| MR02-100 | 100 x 0.05 | 1600 x 1 | 50000 x 20 | 50 x 0.02 | 500 x 0.2 | - |

| MR02-200 | 200 x 0.1 | 3200 x 2 | - | 100 x 0.05 | 1000 x 0.5 | 1 x 0.0005 |

| MR02-500 | 500 x 0.2 | 8000 x 5 | - | 250 x 0.1 | 2500 x 1 | 2.5 x 0.001 |

| MR02-1000 | 1000 x 0.5 | 16000 x 10 | - | 500 x 0.2 | 5000 x 2 | 5 x 0.002 |

| MR02-2000 | 2000 x 1 | 32000 x 20 | - | 1000 x 0.5 | 10000 x 5 | 10 x 0.005 |

| MR02-5000 | 5000 x 2 | - | - | 2500 x 1 | 25000 x 10 | 25 x 0.01 |

| MR02-10000 | 10000 x 5 | - | - | 5000 x 2 | 50000 x 25 | 50 x 0.02 |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| lbF | kgF | N | kN | |

| MR02-100 | 100 x 0.1 | 50 x 0.05 | 500 x 0.5 | - |

| MR02-200 | 200 x 0.2 | 100 x 0.1 | 1000 x 1 | - |

| MR02-500 | 500 x 0.5 | 250 x 0.2 | 2500 x 2 | - |

| MR02-1000 | 1000 x 1 | 500 x 0.5 | 5000 x 5 | - |

| MR02-2000 | 2000 x 2 | 1000 x 1 | 10000 x 10 | - |

| MR02-5000 | 5000 x 5 | 2500 x 2 | - | 25 x 0.02 |

| MR02-10000 | 10000 x 10 | 5000 x 5 | - | 50 x 0.05 |

Dimensions

Ordering Information

| Model | ØA | ØB | C | D | ØE | F | ØG |

| MR02-100 | 1.23 [31.3] |

0.32 [8.1] |

0.05 [1.3] |

0.39 [9.9] |

1.0 [25.4] |

- | 0.83 [21.1] |

| MR02-200 | |||||||

| MR02-500 | |||||||

| MR02-1000 | |||||||

| MR02-2000 | |||||||

| MR02-5000 | 1.48 [37.6] |

0.43 [10.9] |

0.07 [1.8] |

0.62 [15.8] |

1.25 [31.8] |

0.25 [6.4] |

1.08 [27.4] |

| MR02-10000 | |||||||

| SVC014 | Upgrade service BGI style connector to Plug and Test&ftrade; connector | ||||||

Mark-10 Tension and Compression Force Sensors Series R03

Force measurement sensor for tensile and compressive loads in a wide variety of applications, available in capacities from 0.25 lb to 100 lb. Thread on two sides can accept a variety of hooks and implements, making this sensor particularly well suited for inline tests.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Rugged aluminum housing

- Measures tensile and compressive forces

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.15% of full scale ±1 digit + indicator

- Weight: 0.4 lbs (0.2 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||

| lbF | ozF | gF | kgF | N | mN | |

| MR03-025 | 0.25 x 0.0001 | 4 x 0.002 | 100 x 0.05 | - | 1 x 0.0005 | 1000 x 0.5 |

| MR03-05 | 0.5 x 0.0002 | 8 x 0.005 | 250 x 0.1 | - | 2.5 x 0.001 | 2500 x 1 |

| MR03-2 | 2 x 0.001 | 32 x 0.02 | 1000 x 0.5 | 1 x 0.0005 | 10 x 0.005 | - |

| MR03-5 | 5 x 0.002 | 80 x 0.05 | 1000 x 0.5 | 2.5 x 0.001 | 25 x 0.01 | - |

| MR03-10 | 10 x 0.005 | 160 x 0.1 | 5000 x 2 | 5 x 0.002 | 50 x 0.02 | - |

| MR03-20 | 20 x 0.01 | 320 x 0.2 | 10000 x 5 | 10 x 0.005 | 100 x 0.05 | - |

| MR03-50 | 50 x 0.02 | 800 x 0.5 | 25000 x 10 | 25 x 0.01 | 250 x 0.1 | - |

| MR03-100 | 100 x 0.05 | 1600 x 1 | 50000 x 20 | 50 x 0.02 | 500 x 0.2 | - |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| lbF | gF | kgF | N | |

| MR03-025 | 0.25 x 0.0001 | 100 x 0.05 | - | 1 x 0.0005 |

| MR03-05 | 0.5 x 0.0002 | 250 x 0.1 | - | 2.5 x 0.001 |

| MR03-2 | 2 x 0.001 | 1000 x 0.5 | 1 x 0.0005 | 10 x 0.005 |

| MR03-5 | 5 x 0.002 | 1000 x 0.5 | 2.5 x 0.001 | 25 x 0.01 |

| MR03-10 | 10 x 0.005 | 5000 x 2 | 5 x 0.002 | 50 x 0.02 |

| MR03-20 | 20 x 0.01 | 10000 x 5 | 10 x 0.005 | 100 x 0.05 |

| MR03-50 | 50 x 0.02 | 25000 x 10 | 25 x 0.01 | 250 x 0.1 |

| MR03-100 | 100 x 0.05 | 50000 x 20 | 50 x 0.02 | 500 x 0.5 |

Dimensions

Ordering Information

| Model | Description |

| MR03-025 | Force sensor, inline, 0.25 lbF / 1 N |

| MR03-05 | Force sensor, inline, 0.5 lbF / 2.5 N |

| MR03-2 | Force sensor, inline, 2 lbF / 10 N |

| MR03-5 | Force sensor, inline, 5 lbF / 25 N |

| MR03-10 | Force sensor, inline, 10 lbF / 50 N |

| MR03-20 | Force sensor, inline, 20 lbF / 100 N |

| MR03-50 | Force sensor, inline, 50 lbF / 250 N |

| MR03-100 | Force sensor, inline, 100 lbF / 500 N |

| AC1018 | Mounting kit, R01/R03 to force test stands |

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector |

Mark-10 Miniature Force Sensors Series R04

Extremely compact force measurement sensor for tensile and compressive loads in applications with limited space. The Series R04 is available in capacities from 0.25 lb to 100 lb (1 N to 500 N). Every capacity has the same miniature dimensions. The sensors feature outstanding mechanical overload protection and threaded holes on two sides for the mounting of attachments or implements.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Ultra-compact size

- Measures tensile and compressive forces

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.2% of full scale ±1 digit + indicator

- Weight: 0.015 lbs (0.007 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||

| lbF | ozF | gF | kgF | N | mN | |

| MR04-025 | 0.25 x 0.0001 | 4 x 0.002 | 100 x 0.05 | - | 1 x 0.0005 | 1000 x 0.5 |

| MR04-05 | 0.5 x 0.0002 | 8 x 0.005 | 250 x 0.1 | - | 2.5 x 0.001 | 2500 x 1 |

| MR04-2 | 2 x 0.001 | 32 x 0.02 | 1000 x 0.5 | 1 x 0.0005 | 10 x 0.005 | - |

| MR04-5 | 5 x 0.002 | 80 x 0.05 | 1000 x 0.5 | 2.5 x 0.001 | 25 x 0.01 | - |

| MR04-10 | 10 x 0.005 | 160 x 0.1 | 5000 x 2 | 5 x 0.002 | 50 x 0.02 | - |

| MR04-20 | 20 x 0.01 | 320 x 0.2 | 10000 x 5 | 10 x 0.005 | 100 x 0.05 | - |

| MR04-50 | 50 x 0.02 | 800 x 0.5 | 25000 x 10 | 25 x 0.01 | 250 x 0.1 | - |

| MR04-100 | 100 x 0.05 | 1600 x 1 | 50000 x 20 | 50 x 0.02 | 500 x 0.2 | - |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| lbF | gF | kgF | N | |

| MR04-025 | 0.25 x 0.0001 | 100 x 0.05 | - | 1 x 0.0005 |

| MR04-05 | 0.5 x 0.0002 | 250 x 0.1 | - | 2.5 x 0.001 |

| MR04-2 | 2 x 0.001 | 1000 x 0.5 | 1 x 0.0005 | 10 x 0.005 |

| MR04-5 | 5 x 0.002 | 1000 x 0.5 | 2.5 x 0.001 | 25 x 0.01 |

| MR04-10 | 10 x 0.005 | 5000 x 2 | 5 x 0.002 | 50 x 0.02 |

| MR04-20 | 20 x 0.01 | 10000 x 5 | 10 x 0.005 | 100 x 0.05 |

| MR04-50 | 50 x 0.02 | 25000 x 10 | 25 x 0.01 | 250 x 0.1 |

| MR04-100 | 100 x 0.05 | 50000 x 20 | 50 x 0.02 | 500 x 0.5 |

Dimensions

Ordering Information

| Model | Description |

| MR04-025 | Force sensor, miniature, 0.25 lbF / 1 N |

| MR04-05 | Force sensor, miniature, 0.5 lbF / 2.5 N |

| MR04-2 | Force sensor, miniature, 2 lbF / 10 N |

| MR04-5 | Force sensor, miniature, 5 lbF / 25 N |

| MR04-10 | Force sensor, miniature, 10 lbF / 50 N |

| MR04-20 | Force sensor, miniature, 20 lbF / 100 N |

| MR04-50 | Force sensor, miniature, 50 lbF / 250 N |

| MR04-100 | Force sensor, miniature, 100 lbF / 500 N |

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector |

Mark-10 Push/Pull Sensors Series R05

Series R05 fully enclosed smart sensors are designed for pull / push measurements. Useful in ergonomics testing, workplace safety testing, and general lifting or tension / compression requirements. Threaded holes are supplied to accommodate various mounting configurations and attachments. For up to 500 lbF [2,500 N]. Compatible with Mark-10 model M5i and M3i indicators through unique Plug & Test™ technology.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Rugged aluminum housing

- Measures push and pull force

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.15% of full scale + indicator

- Weight: 2.0 lbs (0.9 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||

| lbF | ozF | kgF | N | kN | ||

| MR05-500 | 500 x 0.2 | 8000 x 5 | 250 x 0.1 | 2500 x 1 | 2.5 x 0.001 | |

| Model | Capacity x Resolution (with Model M3i indicator) | ||||

| lbF | gF | kgF | N | kN | |

| MR05-500 | 500 x 0.5 | - | 250 x 0.2 | 2500 x 2 | - |

Dimensions

Ordering Information

| Model | Description |

| MR05-500 | Force sensor, push/pull, 500 lbF / 2500 N |

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector |

Torque Sensors

Mark-10 Universal Torque Sensors Series R50

Measure bi-directional torque for a wide variety of applications. Contains a chuck for samples up to 1/2" in diameter, depending on capacity. The sensor can be used as a hand held device, or mounted to a torque test stand. Capacities available from 10 ozin to 100 lbin.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Rugged aluminum housing

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.35% of full scale ±1 digit + indicator

- Weight: from 1.4 lbs (0.6 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||||

| ozFin | lbFin | lbFft | gFcm | kgFmm | Nmm | Ncm | Nm | |

| MR50-10Z | 10 x 0.005 | - | - | 700 x 0.5 | 7 x 0.005 | 70 x 0.05 | 7 x 0.005 | - |

| MR50-20Z | 20 x 0.01 | - | - | 1400 x 1 | 14 x 0.01 | 140 x 0.1 | 14 x 0.01 | - |

| MR50-50Z | 50 x 0.02 | - | - | 3600 x 2 | 36 x 0.02 | 350 x 0.2 | 35 x 0.02 | - |

| MR50-12 | - | 12 x 0.005 | 1 x 0.0005 | - | 140 x 0.1 | - | 135 x 0.1 | 1.35 x 0.001 |

| MR50-50 | - | 50 x 0.02 | 4 x 0.002 | - | 580 x 0.5 | - | 570 x 0.5 | 5.7 x 0.005 |

| MR50-100 | - | 100 x 0.05 | 8 x 0.005 | - | 1150 x 0.5 | - | 1150 x 0.5 | 11.5 x 0.005 |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| ozFin | lbFin | kgFmm | Ncm | |

| MR50-10Z | 10 x 0.01 | - | 7 x 0.005 | 7 x 0.005 |

| MR50-20Z | 20 x 0.02 | - | 14 x 0.01 | 14 x 0.01 |

| MR50-50Z | 50 x 0.05 | - | 36 x 0.05 | 36 x 0.05 |

| MR50-12 | - | 12 x 0.01 | 140 x 0.1 | 135 x 0.1 |

| MR50-50 | - | 50 x 0.05 | 580 x 0.5 | 570 x 0.5 |

| MR50-100 | - | 100 x 0.1 | 1150 x 1 | 1150 x 1 |

Dimensions

Ordering Information

| Model | A | Chuck Size Range | |||

| MR50-10OZ | 4.82 [122.4] |

0.062-0.375 [1.6 - 9.5] |

|||

| MR50-20OZ | |||||

| MR50-50OZ | |||||

| MR50-12 | 5.19 [131.8] |

0.078 - 0.5 [2.0 - 12.7] |

|||

| MR50-50 | |||||

| MR50-100 | |||||

| Additional Items to Consider | |||||

| AC1007 | Mounting kit, STJ, table top | ||||

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector | ||||

Mark-10 Universal Torque Sensors Series R51

A great solution for general bi-directional torque testing applications requiring different sample sizes. Three interchangeable chuck capacities and bit holder are available. The R51 has superb overload protection and is available in capacities from 10 ozin to 100 lbin.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Outstanding overload protection

- Interchangeable chucks (order separately)

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.20% of full scale ±1 digit + indicator

- Weight: from 1.4 lbs (0.6 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||||

| ozFin | lbFin | lbFft | gFcm | kgFmm | Nmm | Ncm | Nm | |

| MR51-10Z | 10 x 0.005 | - | - | 700 x 0.5 | 7 x 0.005 | 70 x 0.05 | 7 x 0.005 | - |

| MR51-20Z | 20 x 0.01 | - | - | 1400 x 1 | 14 x 0.01 | 140 x 0.1 | 14 x 0.01 | - |

| MR51-50Z | 50 x 0.02 | - | - | 3600 x 2 | 36 x 0.02 | 350 x 0.2 | 35 x 0.02 | - |

| MR51-12 | - | 12 x 0.005 | 1 x 0.0005 | - | 140 x 0.1 | - | 135 x 0.1 | 1.35 x 0.001 |

| MR51-50 | - | 50 x 0.02 | 4 x 0.002 | - | 580 x 0.5 | - | 570 x 0.5 | 5.7 x 0.005 |

| MR51-100 | - | 100 x 0.05 | 8 x 0.005 | - | 1150 x 0.5 | - | 1150 x 0.5 | 11.5 x 0.005 |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| ozFin | lbFin | kgFmm | Ncm | |

| MR51-10Z | 10 x 0.01 | - | 7 x 0.005 | 7 x 0.005 |

| MR51-20Z | 20 x 0.02 | - | 14 x 0.01 | 14 x 0.01 |

| MR51-50Z | 50 x 0.05 | - | 36 x 0.05 | 35 x 0.05 |

| MR51-12 | - | 12 x 0.01 | 140 x 0.1 | 135 x 0.1 |

| MR51-50 | - | 50 x 0.05 | 580 x 0.5 | 570 x 0.5 |

| MR51-100 | - | 100 x 0.1 | 1150 x 1 | 1150 x 1 |

Dimensions

Ordering Information

| Model | Description |

| MR51-1OZ | Torque sensor, universal, 10 ozFin / 7 Ncm |

| MR51-2OZ | Torque sensor, universal, 20 ozFin / 14 Ncm |

| MR51-5OZ | Torque sensor, universal, 50 ozFin / 35 Ncm |

| MR51-12 | Torque sensor, universal, 12 lbFin / 135 Ncm |

| MR51-50 | Torque sensor, universal, 50 lbFin / 570 Ncm |

| MR51-100 | Torque sensor, universal, 100 lbFin / 1150 Ncm |

| G1016-1 | Jacobs chuck for R51, 0.028"-0.25" |

| G1016-2 * | Jacobs chuck for R51, 0.062"-0.375" |

| G1016-3 * | Jacobs chuck for R51, 0.078"-0.5" |

| G1017 | Bit holder for R51, 1/4" hex |

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector |

* Due to the increased possibility of overload resulting from a higher weight attachment used with a lower capacity torque sensor, these attachments are recommended for use only with an MR51-12 or higher capacity model.

Mark-10 Torque Sensor for Tool Calibration Series R52

Calibrate torque tools with this torque measurement sensor, or use it as a component of a torque testing system. Tapped holes on every surface allow for easy mounting to a work bench, or fixture within a testing system. Capacities available from 10 ozin to 100 lbin.

Features & Specifications

Features & Specifications

- Compatible with the M3i, M5i and M7i digital indicators

- Unique Plug & Test™ connector holds all calibration and configuration data

- Rugged aluminum housing

- Universal mounting

- May be used for torque tool calibration or as a component of a torque testing system

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.35% of full scale ±1 digit + indicator

- Weight: 1.2 lbs (0.5 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||||

| ozFin | lbFin | lbFft | gFcm | kgFmm | Nmm | Ncm | Nm | |

| MR52-10Z | 10 x 0.006 | - | - | 700 x 0.5 | 7 x 0.005 | 70 x 0.05 | 7 x 0.005 | - |

| MR52-20Z | 20 x 0.01 | - | - | 1400 x 1 | 14 x 0.01 | 140 x 0.1 | 14 x 0.01 | - |

| MR52-50Z | 50 x 0.02 | - | - | 3600 x 2 | 36 x 0.02 | 350 x 0.2 | 35 x 0.02 | - |

| MR52-12 | - | 12 x 0.005 | 1 x 0.0005 | - | 140 x 0.1 | - | 135 x 0.1 | 1.35 x 0.001 |

| MR52-50 | - | 50 x 0.02 | 4 x 0.002 | - | 580 x 0.5 | - | 570 x 0.5 | 5.7 x 0.005 |

| MR52-100 | - | 100 x 0.05 | 8 x 0.005 | - | 1150 x 0.5 | - | 1150 x 0.5 | 11.5 x 0.005 |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| ozFin | lbFin | kgFmm | Ncm | |

| MR52-10Z | 10 x 0.01 | - | 7 x 0.005 | 7 x 0.005 |

| MR52-20Z | 20 x 0.02 | - | 14 x 0.01 | 14 x 0.01 |

| MR52-50Z | 50 x 0.05 | - | 36 x 0.05 | 35 x 0.05 |

| MR52-12 | - | 12 x 0.01 | 140 x 0.1 | 135 x 0.1 |

| MR52-50 | - | 50 x 0.05 | 580 x 0.5 | 570 x 0.5 |

| MR52-100 | - | 100 x 0.1 | 1150 x 1 | 1150 x 1 |

Dimensions

Ordering Information

| Model | Description |

| MR52-1OZ | Torque sensor, tool calibration, 10 ozFin / 7 Ncm |

| MR52-2OZ | Torque sensor, tool calibration, 20 ozFin / 14 Ncm |

| MR52-5OZ | Torque sensor, tool calibration, 50 ozFin / 35 Ncm |

| MR52-12 | Torque sensor, tool calibration, 12 lbFin / 135 Ncm |

| MR52-50 | Torque sensor, tool calibration, 50 lbFin / 570 Ncm |

| MR52-100 | Torque sensor, tool calibration, 100 lbFin / 1150 Ncm |

| Additional Items to Consider | |

| AC1006 | Mounting kit, STC, table top |

| AC1014 | 3/8" Jacobs chuck for STC |

| SVC014 | Upgrade service BGI style connector to Plug and Test™ connector |

Mark-10 Square Drive Torque Sensors Series R55

This rugged series of torque sensors is ideal for a wide range of torque testing applications in numerous industries. Square drives on both ends permit inline use with a torque wrench, or for use in OEM and other applications. Ranges available up to 5,000 lbFin (550 Nm).

Features & Specifications

- Rugged cylindrical design

- Square drives on each end

- Member of the Plug & Test™ family of interchangeable sensors and indicators

- Stainless steel and aluminum construction

- NIST-traceable certificate of calibration included

- Accuracy: ± 0.6% of full scale + indicator

- Weight: MR55-20 - MR55-1000:1.3 lb (0.6 kg), MR55-5000: 1.9 lb (0.9 kg)

- Warranty: 3 years

Capacity and Resolution

| Model | Capacity x Resolution (with model M5i & M7i indicators) | |||||

| lbFin | ozFin | lbFft | kgFmm | Ncm | Nm | |

| MR55-20 | 20 x 0.02 | 320 x 0.2 | 1.5 x 0.002 | - | 220 x 0.2 | 2 x 0.002 |

| MR55-50 | 50 x 0.05 | 800 x 0.5 | 4 x 0.005 | - | 570 x 0.5 | 5.7 x 0.005 |

| MR55-100 | 100 x 0.1 | 1600 x 1 | 8 x 0.01 | - | 1150 x 1 | 11.5 x 0.01 |

| MR55-200 | 200 x 0.2 | - | 16 x 0.02 | 2300 x 2 | 2200 x 2 | 22 x 0.02 |

| MR55-400 | 400 x 0.5 | - | 32 x 0.05 | 4600 x 5 | 4500 x 5 | 45 x 0.05 |

| MR55-1000 | 1000 x 1 | - | 80 x 0.1 | 11500 x 10 | 11000 x 10 | 110 x 0.1 |

| MR55-5000 | 5000 x 5 | - | 400 x 0.5 | 55 x 0.05 kgFm | 55000 x 50 | 550 x 0.5 |

| Model | Capacity x Resolution (with Model M3i indicator) | |||

| lbFin | ozFin | kgFmm | Ncm | |

| MR55-20 | 20 x 0.02 | 320 x 0.5 | - | 220 x 0.2 |

| MR55-50 | 50 x 0.05 | 800 x 1 | - | 570 x 0.5 |

| MR55-100 | 100 x 0.1 | 1600 x 2 | - | 1150 x 1 |

| MR55-200 | 200 x 0.2 | - | 2300 x 2 | 2200 x 2 |

| MR55-400 | 400 x 0.5 | - | 4600 x 5 | 4500 x 5 |

| MR55-1000 | 1000 x 1 | - | 11500 x 10 | 11000 x 10 |

| MR55-5000 | 5000 x 5 | - | 55 x 0.05 kgFm | 550 x 0.5 Nm |

Dimensions

Ordering Information

| Model | Drive Size | A | B | C | D | ØE | F |

| MR55-20 | 1/4" | 0.30 [7.5] |

1.73 [44.0] |

0.32 [8.0] |

0.39 [10.0] |

1.77 [45.0] |

2.32 [59.0] |

| MR55-50 | |||||||

| MR55-100 | |||||||

| MR55-200 | 3/8" | 0.41 [10.5] |

1.73 [44.0] |

0.43 [11.0] |

|||

| MR55-400 | |||||||

| MR55-1000 | 1/2" | 0.59 [15.0] |

0.63 [16.0] |

||||

| MR55-5000 | 3/4" | 0.89 [22.5] |

2.11 [53.5] |

0.94 [24.0] |

0.77 [19.5] |

2.01 [51.0] |

2.56 [65.0] |

Features & Specifications

Features & Specifications